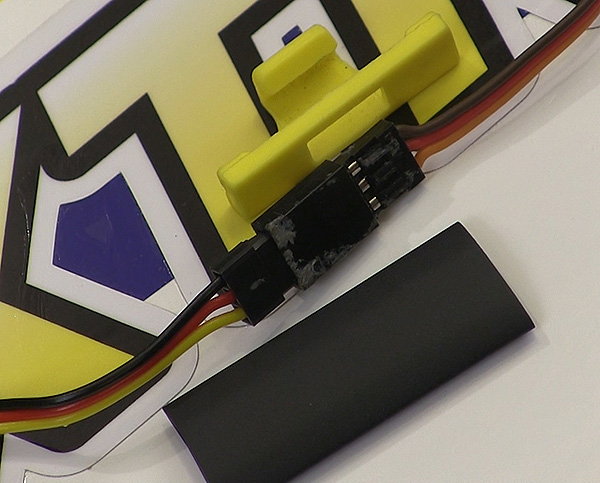

I know lots of people use plastic clips to secure servo extensions. I like to apply

shrink tubing as I think it is more secure and makes pulling cables through

structure easier.

Text, photos and video by Tom Hintz

Posted – 11-5-2015

One of the downsides to ARF (almost ready to fly) aircraft is feeding long servo wires and extensions through structures like wings and tail sections. The manufacturers usually leave strings (would another 3 or 4 inches of string really be cost prohibitive?) and that certainly helps. However there is another catch, actually potentially lots of catches. There is a simple way to make this task easier and the connection more secure. Plus, you probably have the needed supplies in your shop right now.

Most manufacturers supply little plastic clips that lock servo extension connections together. These really are useful pieces, particularly to secure connections we have to make to assemble a plane for flight. Those clips are critical for securing aileron connections when installing wings. But for more permanent connections, like extensions that run through wings and tail sections shrink tubing makes more sense. It is easy to do and eliminates lots of the catches we fight when trying to snake wires with those plastic clips on connections through the structure of wings and tail sections.

I find that 3/8”-wide shrink tubing fits best both for getting it on the connection and then for shrinking it down snugly. The first thing to do is make sure that the extension you have chosen is actually the right length for the job. I have eye balled this dimension before and came up a little short so take the time to check the fit first.

Assemble the connection and cut a piece of shrink tubing roughly 1/2” longer than the assembled connection. That seems to be plenty for locking the connection itself down and streamlining the connection at the wires on either end.

Slip the shrink tubing over the wire and down to the connection. Make sure that the tubing extends over the wires on either end before applying heat to shrink it down. I use a grill lighter and turn the connection over frequently to draw the tubing down equally. Working your way around the connection also prevents over heating any one portion of the tubing or the wires themselves. It’s not going to help having a secure connection and melted wire coating.

The shrink tubing doesn’t close down tight on the wires like it does on the connection itself but it does come close. More importantly it creates a “ramp” up and over the connection that help it slip through the airframe much easier than the plastic clips.

In the end you have a very secure connection that is not going to slip apart under vibrations and even slight pulling forces. Plus the connection is sealed against dust and other contaminants. This is a simple and cheap way to secure permanent servo extensions that can also make installation easier.

Have a comment on this How-To? –Email Me!